Sinus Machine is a Turkish company based in Kocaeli that produces high-quality sandwich panel machines since January 2019. Its machines are known for their precision, efficiency, and reliability and used by manufacturers worldwide. Sinus Machine also provides technical training and support to its customers and is dedicated to quality, innovation, and customer satisfaction. If you are in need of a solution for the production of sandwich panels, Sinus Machine is a reliable choice.

Maximizing Efficiency with PU-PIR Sandwich Panel Production Machines

Sandwich panels are an essential building material that offers a range of benefits including insulation and stability. The PU-PIR sandwich panel is a type of sandwich panel that uses polyurethane (PU) and polyisocyanurate (PIR) foam as the core material, providing excellent insulation and fire resistance properties.

To produce high-quality PU-PIR sandwich panels, a specialized machine is required, and that’s where PU-PIR sandwich panel production machines come into play. These machines are designed to produce sandwich panels with a consistent thickness and smooth surface finish, ensuring that the panels meet the highest standards of quality and performance.

PU-PIR sandwich panel production machines are specialized machines designed to produce high-quality PU-PIR sandwich panels efficiently and effectively. These machines offer increased efficiency, consistent quality, easy operation, and durability. Choosing the right machine with strong after-sales support is crucial for manufacturers looking to produce PU-PIR sandwich panels efficiently and achieve improved profitability.

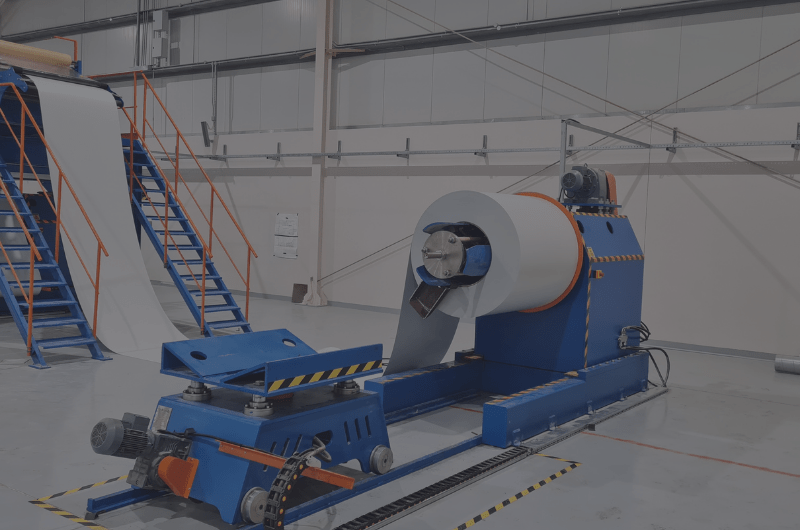

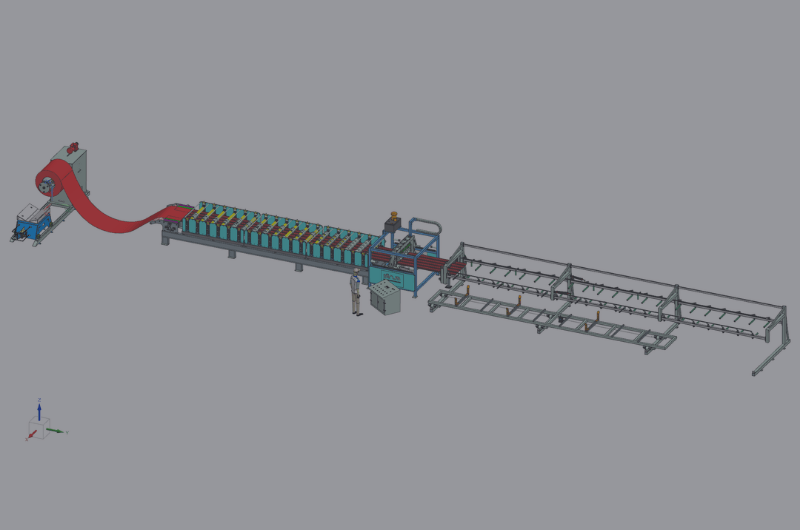

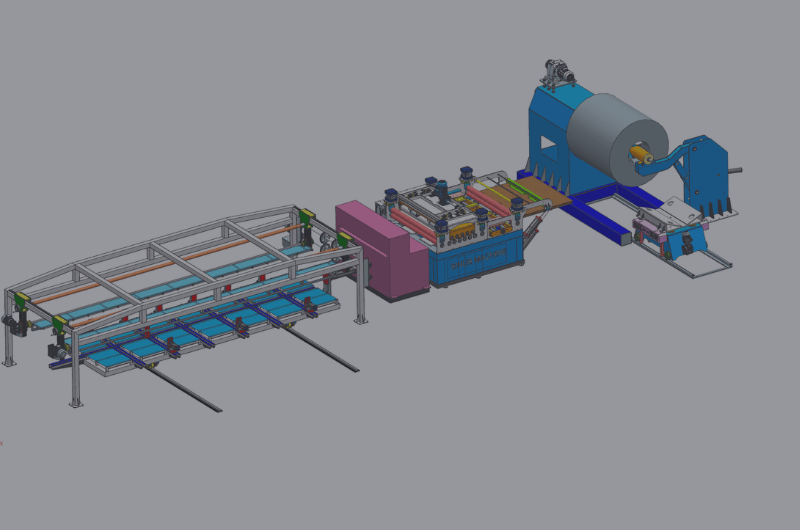

An Example System(s) We Put into Production:

Our Services

The products and services we have provided.

Sandwich Panel Production Machine

Trapezoidal Sheet Production Machine

Cut to Length Line

Polyurethane Foam Machine

Companies We Serve

Companies that ``trust`` us.

PU-PIR Sandwich Panel Production Machine

A PU-PIR Sandwich Panel Production Machine is a device used to produce PU-PIR (polyurethane-polyisocyanurate) sandwich panels, a type of insulation material used in building construction. The panels are made by sandwiching a core of polyurethane or polyisocyanurate foam between two metal sheets, typically galvanized steel or aluminum.

The PU-PIR sandwich panel production machine automates the entire production process, from the cutting and rolling of the metal sheets to the foaming and curing of the foam core. This helps to ensure consistent quality and uniformity in the final product.

PU-PIR sandwich panels offer a range of benefits for building construction. They provide excellent insulation properties, helping to reduce energy costs and increase comfort levels in buildings. They are also lightweight, making them easy to install and handle, and they are resistant to fire and other environmental factors, making them a durable and long-lasting insulation solution.

The versatility of PU-PIR sandwich panels makes them suitable for use in a variety of applications, including walls, roofs, and partition walls. They can be produced in a range of sizes, thicknesses, and surface finishes, depending on the specific requirements of each project.

In conclusion, the PU-PIR Sandwich Panel Production Machine is an essential piece of equipment for the production of PU-PIR sandwich panels, a versatile and durable insulation material used in building construction. Its efficiency and ability to produce panels of various sizes and finishes make it a valuable tool in the industry.

We are ready to help, reach out to us.

With our experienced team, we are ready to support you, especially in the field of sandwich production lines.